Search Website

Search Website

Search Website

Search Website

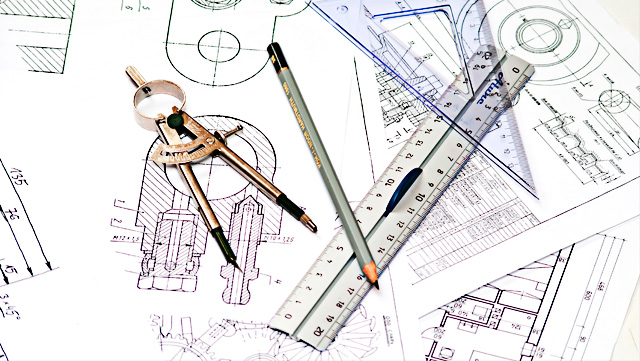

With our team of professional engineers, we help you to understand what needs to be done to make your product quieter, lighter, cooler and safer.

We develop design criteria and work with closely with you to co-develop concepts for project feasibility.

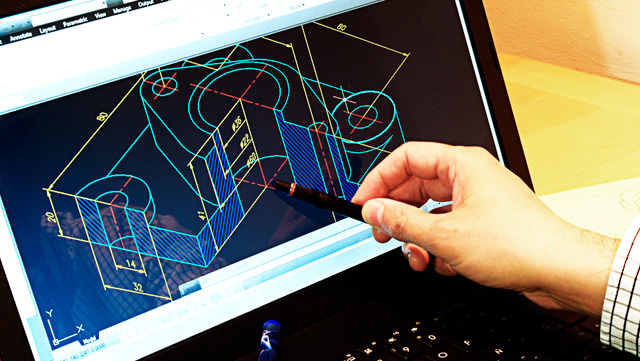

In the early stage of development where a physical model of the product doesn’t exist, we use software (such as CAD, CATIA V5, Unigraphics NX, etc) to help develop the design, fit and finish.

Our Engineers explore all possibilities by creating sample parts which allows you to perform trials and tests before final production.

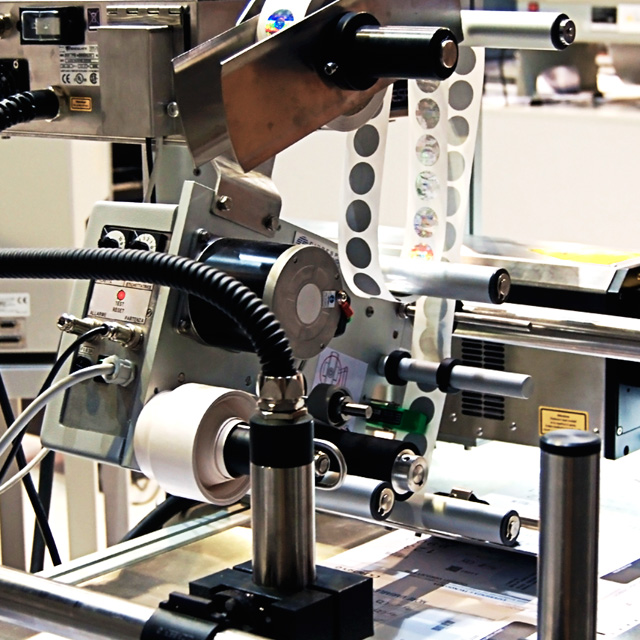

Upon a successfully validated prototype solution, we build a manufacturing line for commercial mass production.

Our production sites features in-house Material Laboratory as well as our state-of-the-art Analytical Laboratory. All testing undergo stringent Quality Control and Quality Assurance by our team of experts, ensuring the product meets various customer’s requirement in a reliable and accurate manner.

As an integrated one-stop solution provider, Armstrong Odenwald provide services for product assembly, label printing, lamination and adhesive coating for all your manufacturing needs.